Quality & Certifications

The aerospace industry is based on quality assurance. AMI has an experienced team of Quality professionals that inspect and certify all incoming, in-process production and finished products according to the highest industry standards and customer specifications.

AS9100D certified, ISO9001:2015 certified, Nadcap accredited for welding, and US ITAR registered.

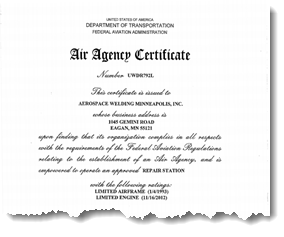

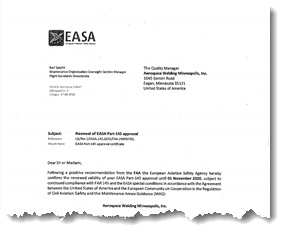

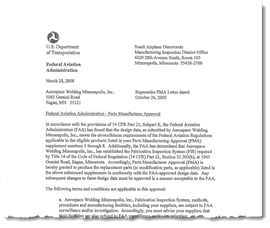

FAA 145 Repair Station (UWDR792L), FAA / PMA Manufacturer (PQ2712CE), EASA Accredited (EASA.145.6155)

AMI has a full contingent of QA Engineers and technicians to meet the most stringent aviation standards.

Our QUALITY Equipment includes:

- Mitutoyo 7106 Crysta – Apex S CMM (40? x 25? bed)

- OGP SP332 Vision System w/scanning touch probe

- CMM Romer Arm

- 9′, 7 axis Hexagon 85 with a tube inspection arm (Power Inspect)

- 6′, 6 axis (Power Inspect)

- Olympus X-ray – Fluorescence Hand Held Analyzer

- (2) Large Calibrated Surface Tables

- Various precision QA measuring instruments and gauges

- Profilometer

- Ultra Sound Thickness Gauge

- (1) Optical Comparator (X20, X50)

- (3) Olympus Video Boroscopes (Capable of near focus/far focus/sideview/front view)

Approved Supplier to the following

Certificates and Registrations

Click here to read AMI General Terms and Conditions.